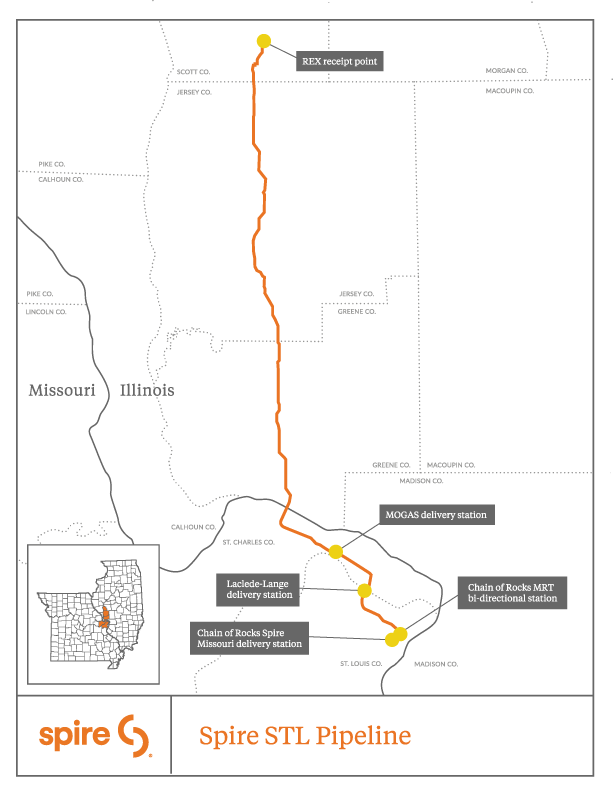

With the STL Pipeline, we've created more diversity in our energy supply

This means more reliability for our distribution customers and lower rates for customers in the St. Louis market.

The pipeline helps us meet the region's growing energy and economic development needs to better serve customers, while encouraging new commercial and industrial growth opportunities in the region.

And, it also eliminates the need for back-up propane systems, resulting in lower emissions and reduced maintenance costs.

Doing what's best for customers is doing what's best for the environment

Protecting the environment is important to us. Like you, we want to preserve sensitive areas and endangered species. From planning through construction, and with regular maintenance now that the pipeline is in use, we will do everything we can to protect the environment.

We partnered with an environmental firm to carefully study the route and identify any ecological and archeological concerns. The pipeline route was adjusted to ensure requirements were met to protect the environment.

During construction, we used modern and less disruptive methods, such as horizontal directional drilling to avoid disturbing sensitive areas and minimize environmental impacts.

As an interstate project, the Spire STL Pipeline has been reviewed for siting and permitting by the Federal Energy Regulatory Commission (FERC). The FERC was the lead agency for other federal and state, and local permitting authorities. The pipeline is wholly owned and operated by Spire STL Pipeline LLC.